Estructural Repairs & Reinforcements

Experts in Epoxy injection and Anchor bolts repair and replacement

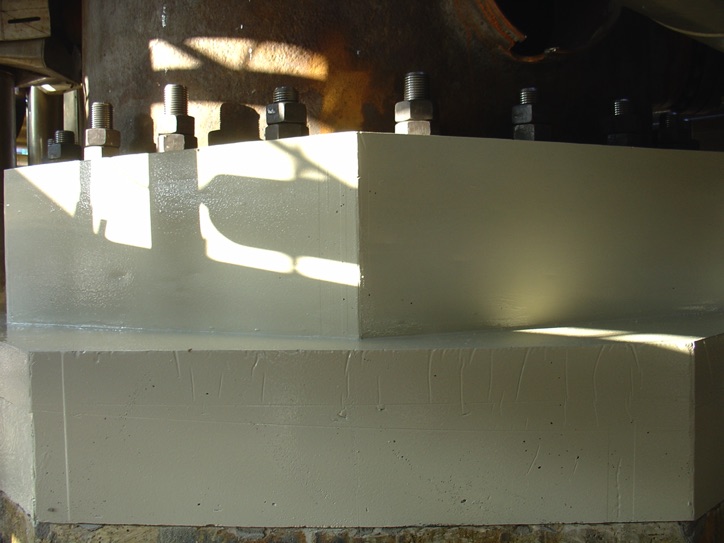

Foundation Consolidation

All different kinds of foundation designs have been highly successful repaired and upgraded with this technology.

Epoxy resin injection

Skid mounted machinery injection: This filling process however generates voids and gaps between the steel skid and the concrete due to shrinkage. Apoltec developed an injection system using our Apoltec 300 modified epoxy-polymer adhesive to fill those voids and gaps to bond all components achieving a perfect monolithic foundation

Anchor bolts repair and replacement

Apoltec can provide a wide range of solutions in case of an anchor bolt break.

We can provide the design and realize the installation of all sizes of anchor bolts.

Structural Reinforcements

If you have lack of stability due to a structure design problem or a degradation due to the corrosion, do not hesitate to contact us. We have experience applying fiber, and design and building epoxy reinforcements.

FAQ

Any structure submitted to an aggressive environment (marine, petrochemical, several industrial processes) is exposed to constantly physical and chemical attacks, drawing to material pathologies. This alters its mechanical and functional features leading to poor performance, even putting it out of order and risking safety operation.

For a proper maintenance, APOLTEC systematically studies the current dysfunctions and regularly carries out analysis, test, and its evaluation in order to determine the pathology progression and severity damage.

Reinforced concrete structures.

Main causes of pathologies: atmospheric gases, salty, acid and selenium waters, organic products and fire

Pathologies: disintegration, ettringit formation, carbonatation, rebar corrosion,…

Main symptoms: cracks, swelling, spilling, colour changes, efflorescence,…

Steel structures.

Chemical, physical, mechanical, even, biological influences trigger out pathological processes derived from material composition and/or the construction design applied.

As main damages we could find laminar tearing, excessive deformations, fatigue, wearing and mainly corrosion and oxidation processes.

Technical solutions.

To disguise the symptoms is not the proper way to confront the problem. It´s requested a thoroughly survey which lead us to discover the core to stop the damage progression, to protect materials, to reinforce where needed for releasing critical stresses and, finally, recoup forms with the best suitable materials.

The anchoring system is essential to constrain / restrain the inertias and moments.

The anchoring system is conceived to apply evenly distributed compression strength to counteract the balanced and unbalanced forces; and also to provide compression strength to the surrounded materials (grout and top part of the concrete foundation) due to its shortage of tensile and shear resistance.

The anchoring system is designed to resist fatigue under normal stresses (given by compression-traction cycles). When it is submitted by tangential ones (flexural and shear forces; torsion and flexural moments) for which they are not design, bolts’ failure are achieved sooner or later.

And that happens when the anchor bolts start loosening the tension (lessen torque requests’) due to many reasons, but mainly oil penetration, corrosion, grout contact surface degradation, cracks, and so on.

To improve the anchoring system, request certain performances:

- Repair the anchoring system by coring out the existing damaged bolt and embedding a straight new one.

- Replacing by new bolts or connecting the upper new one by a threaded sleeve to the existing one.

- Check the tightness and re-tight at the specified torque according to the bolt material, the manufacturer requests’ and the grout compression strength by controlling the elongation (for the stretching length) of the bolt and the real bearing area of grout

Apoltec has more than 30 years of experience consolidating foundations with our specialized products for high pressure Apoltec Epoxy injection. This injection restores stability and integrity to the foundations, additionally our resin displaces the oil and corrosive products expelling them through the cracks, being filled with epoxy and returning the integrity and consistency to the original foundation.

Consistency is lost due to different factors, such as:

- Filtration of corrosives

- Cracks generated by vibrations and material degradation

- Internal corrosion of foundation materials, etc.

At Apoltec we are specialists in the injection and repair of foundations that have lost stability due to any of these causes. We have the materials, the human team, and the necessary experience for its rapid repair.

We have been repairing anchor bolts for more than 30 years and restoring foundations stability that have lost consistency. Our clients are 100% satisfied and recommend us.